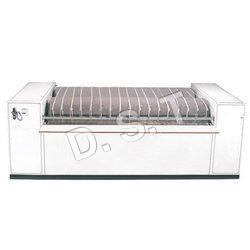

Calendering Machine

Price 510000 INR/ Unit

Calendering Machine Specification

- Style

- Horizontal roller type

- Temperature

- Working range up to 120C (Max)

- Fuel Type

- Electric

- Output

- Smooth and uniform sheet finish

- Pressure

- Adjustable up to 80 tons

- Fuel Consumption

- Low (Electric powered)

- Condition

- New

- Voltage

- 380V / 50Hz

- Heat Efficiency

- Up to 90%

- Part Type

- Industrial Calender Unit

- Dimension (L*W*H)

- Approx. 3500mm x 1200mm x 1700mm

- Function

- Surface finishing, smoothing, and thickness adjustment of paper or fabric

Calendering Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 Week

About Calendering Machine

We bring forth a remarkable range of Calendering Machine that is used in laundries for ironing garments in very less time. Offered machine is manufactured at our state-of-the-art manufacturing unit using pioneering technology and quality approved components procured from trusted vendors of market. Offered Falt work Ironer is tested under the vigilance of quality professionals and can be availed at affordable prices.

Features ofCalendering Machine:

-

Energy efficient

-

Easy to operate

-

Strong construction

-

Low maintenance

Technical details

|

Material |

Cost Iron |

|

Type |

Two Roll |

|

Power |

5 - 40 HP |

Versatile Calendering for Multiple Industries

With its adaptable design, this calendering machine suits diverse manufacturing sectorsfrom paper mills to textile, rubber, plastics, and film processing plants. Adjustable settings allow for tailored finishing solutions across materials. Its robust build and excellent heat efficiency make it a top choice for high-volume operations.

Advanced PLC Digital Control

The integration of a PLC digital control system simplifies operation, enhances repeatability, and boosts safety. Operators can fine-tune pressure, temperature, and roller speed, ensuring consistent results and easy process adjustments for different materials. This modern control platform also aids in efficient troubleshooting and process monitoring.

Engineered for Safety and Efficiency

Equipped with emergency stop, overload protection, and below 75 dB operation, this machine ensures operator safety and workplace comfort. The automatic centralized lubrication and low electric fuel consumption contribute to its cost-effective, low-maintenance operationmaximizing uptime while minimizing operating expenses.

FAQs of Calendering Machine:

Q: How does the PLC digital control system enhance the calendering process?

A: The PLC digital control system allows for precise adjustments of pressure, temperature, and roller speed. It automates the machines operation, provides real-time monitoring, and facilitates accurate and repeatable finishing on various materials, improving both productivity and quality.Q: What materials can be processed with this calendering machine?

A: This machine is suitable for calendering paper, textiles, rubber, plastics, and film. The adjustable settings and robust design make it versatile enough to handle a wide range of industrial applications.Q: When is it beneficial to use a calendering machine for material finishing?

A: A calendering machine is especially valuable during the final stages of the manufacturing process when a smooth, uniform finish and precise thickness adjustment are required for materials such as paper, fabric, or film.Q: Where is this calendering machine typically installed and used?

A: Due to its floor-mounted, industrial design, this machine is typically installed in manufacturing facilities or processing plants requiring high-volume, precision finishing of sheet materials.Q: What safety features are included with the machine?

A: For operator protection and reliable operation, the machine comes equipped with an emergency stop function, overload protection, and operates at a low noise level under 75 dB, ensuring a safer and more comfortable work environment.Q: How does the automatic lubrication system benefit the user?

A: The automatic centralized lubrication system maintains optimal roller and bearing performance, reduces routine maintenance requirements, and contributes to the overall longevity and consistent performance of the machine.Q: What are the main benefits of using this industrial calender unit?

A: Key benefits include smooth and uniform surface finishing, improved material flatness, reduced labor through automation, high heat efficiency (up to 90%), energy-saving electric operation, and enhanced workplace safety and comfort.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machines Category

Steam Iron STB 200

Price 3250 INR / Unit

Minimum Order Quantity : 1 Piece

Condition : New

Material : Plastic and Metal

Pressure : Other, Up to 4 Bar

Voltage : 220240 V

All Steam Press ( Lever Set )

Price 2400 INR / Unit

Minimum Order Quantity : 1 Piece

Condition : New

Material : Brass, Stainless Steel, Mild Steel

Pressure : Other, 36 Bar (as applicable to application)

Voltage : Matches iron/boiler circuit, typically 220V/440V

Steam Boiler parts

Price 370 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Material : Mild Steel, Stainless Steel, Cast Iron

Pressure : Other, Up to 20 Bar

Voltage : 220V/380V

Vacuum Ironing Table for Garment Industry

Price 25000 INR / Unit

Minimum Order Quantity : 1 Piece

Condition : New

Material : Mild Steel

Pressure : Vacuum Pressure PSI

Voltage : 220 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free