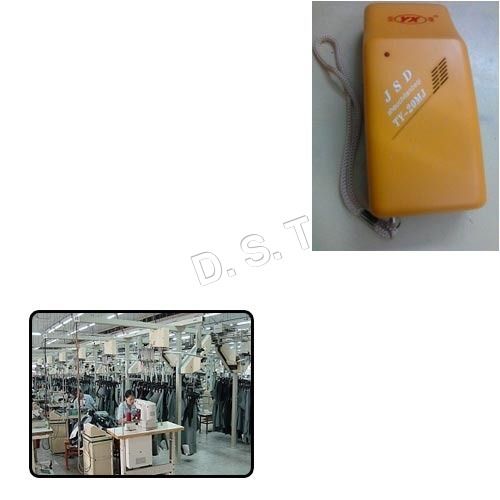

Portable Needle Detector Machine

Price 5800 INR/ Unit

Portable Needle Detector Machine Specification

- Condition

- New

- Color

- Grey

- Operate Method

- Handheld, Manual

- Feed Mechanism

- Automatic

- Voltage

- 220V AC

- Needle

- For all needle types (detection)

- Power

- 5W

- Dimension (L*W*H)

- 320 x 135 x 110 mm

- Product Type

- Portable Needle Detector Machine

- Detection Area

- 60 mm width

- Usage

- For final inspection of garments for broken needles

- Battery Type

- Rechargeable battery/AC Adapter

- Application

- Garments, Toys, Textiles

- Portability

- Lightweight and Compact Design

- Detection Sensitivity

- 0.8 mm iron balls

- Operating Temperature

- -10°C to 40°C

- Net Weight

- Approximately 800 grams

- Body Material

- High-impact Plastic Body

- Display

- LED Indicator

- Alarm Method

- Audio and Visual Alarm

Portable Needle Detector Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Year

- Delivery Time

- 1 Week

About Portable Needle Detector Machine

Our Portable Needle Detector machine is mainly used for application where metal chips inside fabric, food, sewing,chemical and pharmaceutical products. It find needle with the help of sensors of cycled magnetic. Moreover, it has a light indicator and touch panel display. Our Portable Needle Detector has smart report system that provides different sorts of information in total production, time consumes, number of parts dismissed and various others. It ensure that a discharged part is excepted at the time of even by fault.

Technical detailsofPortable Needle Detector Machine:

|

Alarm Method |

Buzzer, Lamp |

|

Model |

JSDST25 |

|

Machine Type |

Manual |

|

Rated Output |

30 W |

|

Detection Area |

160 mm x 500 mm |

Precise Detection Capability

Engineered to locate even 0.8 mm iron balls, this needle detector guarantees thorough inspection across garment, toy, and textile items. Its 60 mm wide detection area covers more surface in less time, reducing inspection errors and helping you maintain stringent quality standards.

Simple Operation and Portability

Weighing approximately 800 grams and featuring a compact grey design, the machine is easy to transport and handle. Its handheld, manual operation and LED display simplify the inspection process, making it ideal for mobile quality control teams or small workshops.

Versatile Power Options for Flexibility

This unit operates with a rechargeable battery or an AC adapter at 220V AC, ensuring reliable performance whether used on the shop floor or off-site locations. With only 5W power consumption, it offers an energy-efficient solution for continuous inspection tasks.

FAQs of Portable Needle Detector Machine:

Q: How does the Portable Needle Detector Machine work for garment inspection?

A: The device utilizes audio and visual alarms, along with a sensitive detection system that identifies traces of broken or lost needles in garments, toys, and textiles. Its LED indicator instantly alerts users to the presence of metallic contaminants during manual inspection.Q: What types of needles can this machine detect?

A: This detector is suitable for all needle types found in garment manufacturing. It can sense even small metallic pieces, such as 0.8 mm iron balls, ensuring comprehensive inspection for safety and quality.Q: When should the needle detector be used in the manufacturing process?

A: It is recommended to use the needle detector during the final inspection stage before packaging and dispatch. This ensures all finished products are free from unwanted metal fragments, thus meeting safety regulations and export standards.Q: Where is the Portable Needle Detector mostly utilized?

A: Manufacturers and exporters in the garment, toy, and textile industries use this machine, particularly in final inspection areas, production floors, and quality control rooms where thorough checks for needle fragments are required.Q: What is the process for operating the needle detector?

A: Simply power the device using either the rechargeable battery or AC adapter, then glide the handheld unit over the item being inspected. The automatic feed mechanism and LED display provide real-time alerts if metal is detected.Q: What are the benefits of choosing this portable needle detector?

A: Its lightweight construction, high detection accuracy, dual power modes, and easy manual operation deliver convenience and dependability for efficient and safe quality control. The compact design also allows easy transport between inspection stations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Detectors Category

Automatic Needle Detector Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 , , Piece

Dimension (L*W*H) : 1200 x 700 x 900 mm

Product Type : Automatic Needle Detector Machine

Needle : Detection Function Only

Power : 90W

Handy Needle Detector Machine

Price 6000 INR / Unit

Minimum Order Quantity : 1 , , Piece

Dimension (L*W*H) : 19 cm x 5.5 cm x 4.5 cm

Product Type : Handy Needle Detector Machine

Needle : Detects Broken Needles/Ferrous Objects

Power : Low Power Consumption

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS