Steam Boiler Parts

Price 300 INR/ Piece

Steam Boiler Parts Specification

- Output

- Ensures reliable steam or hot water output as per boiler design

- Voltage

- N/A (unless electrical component, can be customized)

- Life Span

- 1520 years with standard maintenance

- Fuel Type

- Compatible with Coal, Oil, Gas, Biomass depending on boiler specification

- Pressure

- Withstands up to 32 Bar (varies as per part design specifications)

- Condition

- New

- Temperature

- Withstand up to 550C depending on part

- Capacity

- Suitable for boilers with capacity ranging from 500 kg/hr to 50,000 kg/hr

- Style

- Industrial, Flanged/Non-flanged, Welded or Threaded

- Fuel Consumption

- Depends on full boiler system and part configuration

- Heat Efficiency

- Supports up to 9095% overall boiler efficiency (when fitted correctly)

- Material

- Stainless Steel, Mild Steel, Cast Iron (as per requirement)

- Part Type

- Boiler Tube, Header, Water Wall, Superheater, Economizer, or customized part

- Dimension (L*W*H)

- Customized as per part requirement or drawing

- Function

- Supports heat exchange, steam generation, controls, or water circulation

- Packing Type

- Wooden crate or as per export standard

- Corrosion Resistance

- High corrosion resistance due to material choice and surface treatment

- Manufacture Standard

- IS, ASTM, BS, DIN standards as applicable

- Customization

- Available as per drawing or end-use specification

- Surface Finish

- Polished, Painted, or Coated as per customer requirement

- Application

- Power plants, Textile, Chemical, Food & Beverage Industry, etc.

- Welding Technology

- TIG/MIG/Arc welded for strength

- Component Replaceability

- Designed for easy replacement and minimal downtime

Steam Boiler Parts Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 Week

About Steam Boiler Parts

As per specified requirements of our clients, we have been engaged in manufacturing, exporting and supplying a gamut of Steam Boiler Parts. The offered parts are manufactured under the supervision of our deft professionals using supreme quality basic materials with the aid of innovative techniques. These parts are widely used in chemical, pharmaceutical and metal fabrication industries. In addition to this, the provided Steam Boiler Parts are available in several specifications at economical prices.

Features of Steam Boiler Parts:

- Low maintenance

- Robust construction

- Noise-free operation

- Strong metallic surface

Superior Corrosion Resistance and Longevity

Every boiler part leverages advanced materials and surface treatments for exceptional corrosion resistance, helping to extend operational life to 1520 years with regular maintenance. This ensures system reliability and significantly reduces maintenance frequency in demanding industrial settings.

Custom-Engineered for Versatility and Efficiency

Parts are designed as per customer specifications or drawings, supporting compatibility with various boilers, fuel types, and industry requirements. Whether you need flanged, non-flanged, welded, or threaded components, our products maintain 9095% boiler efficiency and withstand up to 550C and 32 Bar pressure.

FAQs of Steam Boiler Parts:

Q: How are the steam boiler parts protected against corrosion?

A: Our boiler parts utilize high-grade stainless steel, mild steel, or cast iron, coupled with advanced surface finishes such as polishing, painting, or protective coatings. These measures deliver robust corrosion resistance, extending component lifespan in challenging industrial environments.Q: What standards do the steam boiler parts adhere to?

A: All our parts comply with prominent international standards including IS, ASTM, BS, and DIN. This ensures reliable performance, safety, and universal compatibility across diverse industrial applications.Q: When should steam boiler parts be replaced or serviced?

A: Parts should be checked and maintained regularly as part of your preventive maintenance regime. Typically, with proper care, these components last 1520 years. Easy-replacement designs help ensure minimal downtime when servicing or replacing is required.Q: Where are these corrosion-resistant boiler parts commonly used?

A: These parts find application in power plants, textile factories, chemical processing units, and the food & beverage industry, among others. Theyre versatile, supporting a wide array of industrial boilers and operating conditions.Q: What is the process for customizing a boiler part to specific needs?

A: Customization is available according to customer-supplied drawings or end-use specifications. Our engineering team collaborates to design, fabricate, and finish parts to meet particular dimension, material, and performance requirements.Q: What are the benefits of choosing these boiler parts for my facility?

A: Choosing these parts ensures excellent resistance to wear and corrosion, high heat transfer efficiency (up to 95%), reliable performance, and straightforward replacement. This increases energy savings, reduces operational interruptions, and extends equipment life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machines Category

All Steam Press ( Lever Set )

Price 2400 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Brass, Stainless Steel, Mild Steel

Style : Other, Industrial Lever Mechanism

Voltage : Matches iron/boiler circuit, typically 220V/440V

Condition : New

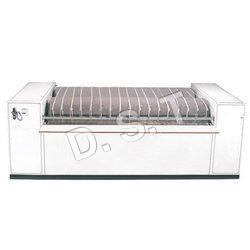

Calendering Machine

Price 510000 INR / Unit

Minimum Order Quantity : 1 , , Piece

Style : Other, Horizontal roller type

Voltage : 380V / 50Hz

Condition : New

Handy type Needle Detector

Price 4600 INR / Unit

Minimum Order Quantity : 1 Piece

Material : ABS Plastic

Style : Other, Portable / Handy

Voltage : 9V (Dry Battery Powered)

Condition : New

I.P.S. 2-6 Bars

Price 550 INR / Unit

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel

Style : Other, Compact, Surface Mountable

Voltage : 220V AC / 24V DC

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS